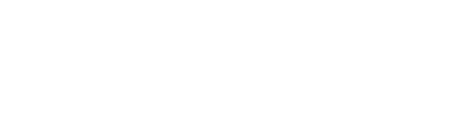

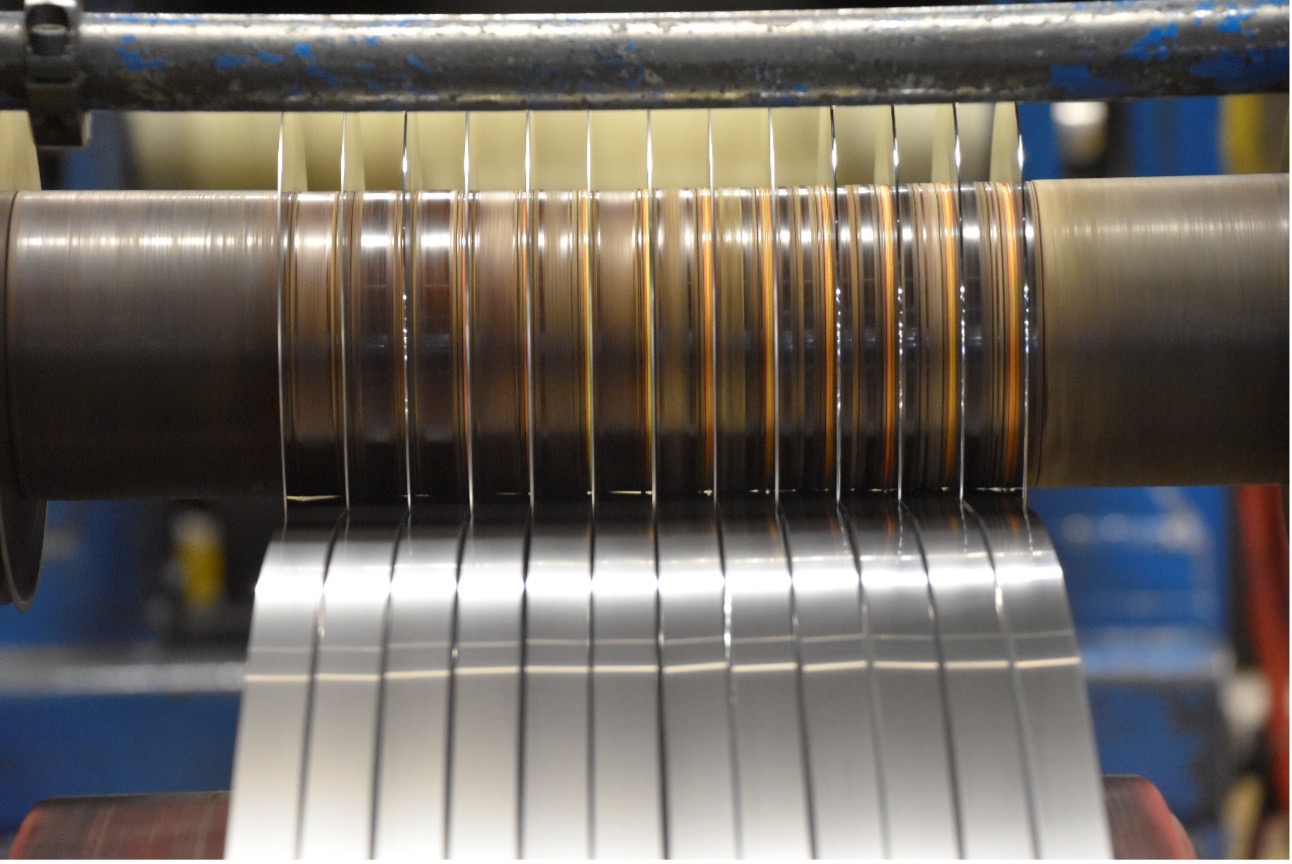

The Use of Stainless Steel in the Medical Field: Insights from a Stainless Steel Slitting Company in Birmingham, Alabama

Stainless steel is used in a wide range of medical applications today. This is due largely to the fact that medical-grade stainless steel is an economical and versatile material. Are you interested in learning why stainless steel is such a popular material in the medical industry? If so, you’ve come to the right place […]