What Are the Unique Qualities of Stainless Steel? Insights from NKS – A Stainless Steel Slitting Company in El Paso, Texas

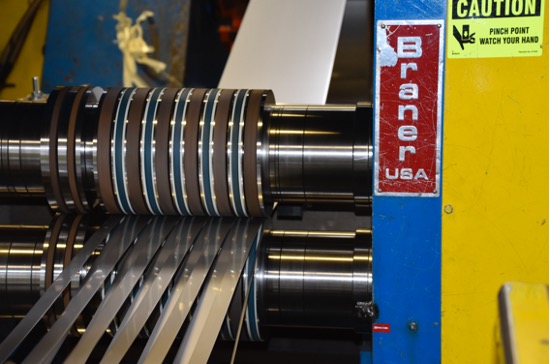

Stainless steel is a versatile and durable material that has become an essential component in various industries, from construction to manufacturing. One of the critical processes in the stainless steel industry is slitting, which involves cutting wide coils of stainless steel into narrower strips or sheets. This process requires precision, expertise, and specialized equipment […]

English

English