Comparing The 301 And 304 Stainless Steel Variations: Insights from a Stainless Steel Distributor and Slitting Company

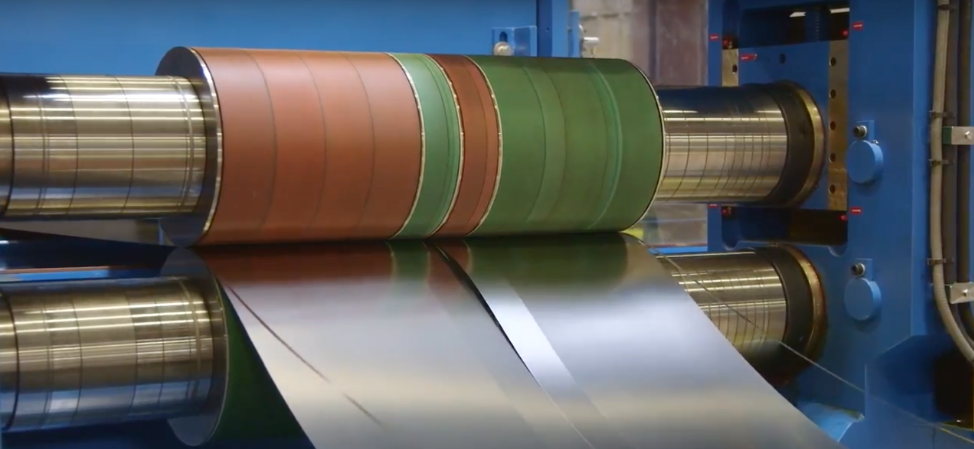

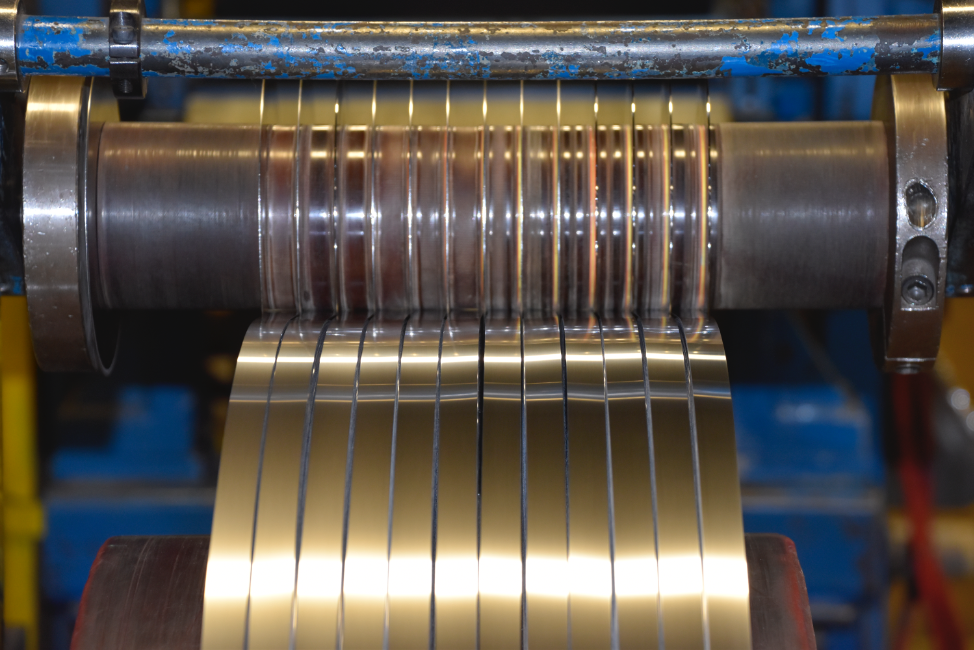

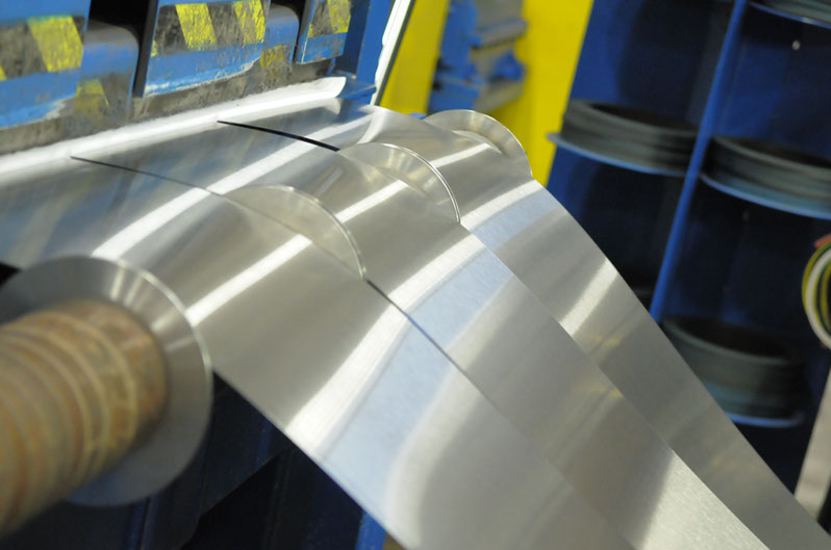

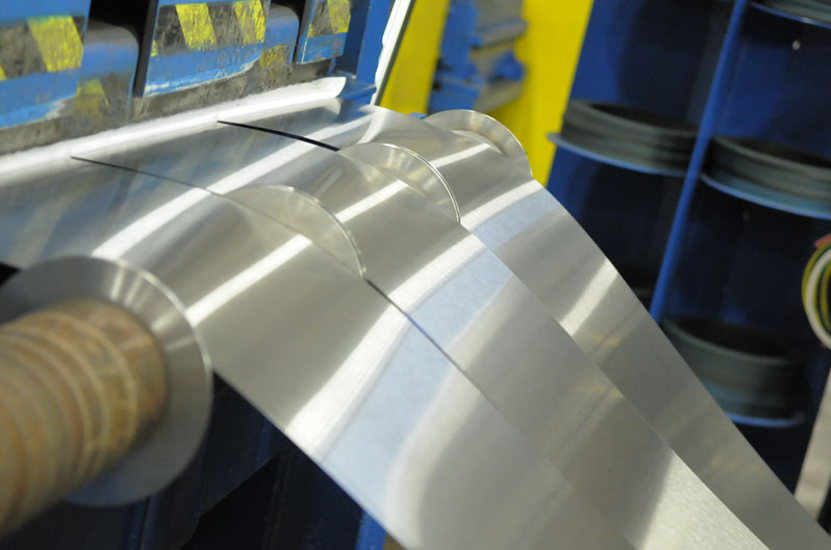

At NKS, we offer a variety of stainless steel variations, each with its own strengths and weaknesses. Choosing the right material for your 301 and 304 stainless steel slitting needs can make the difference between developing a product that lasts for years, and one that will have frequent failures throughout its lifespan. However, given […]

English

English