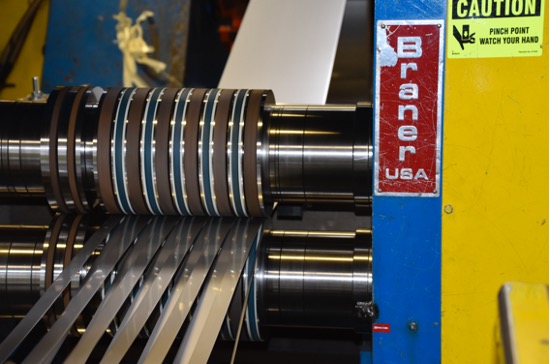

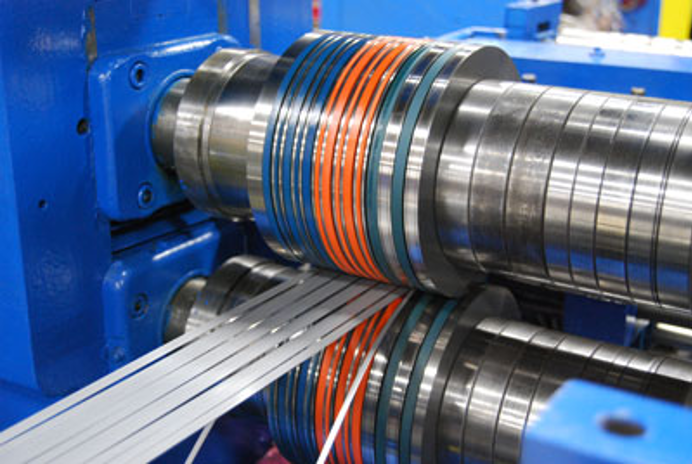

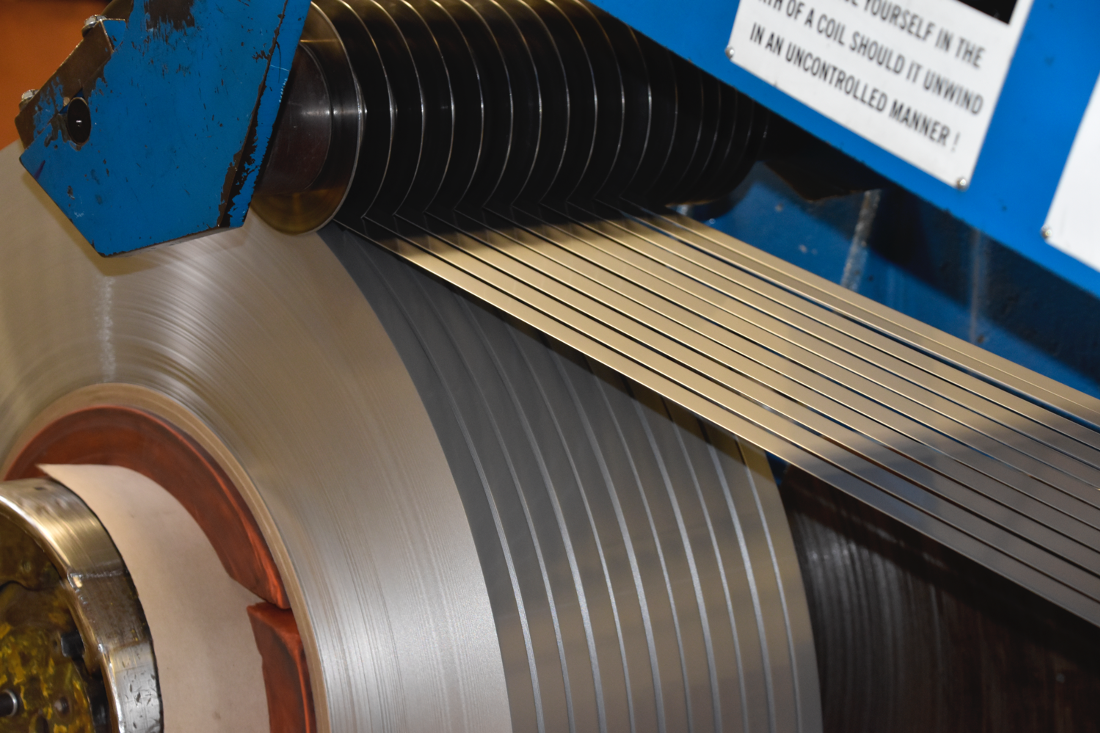

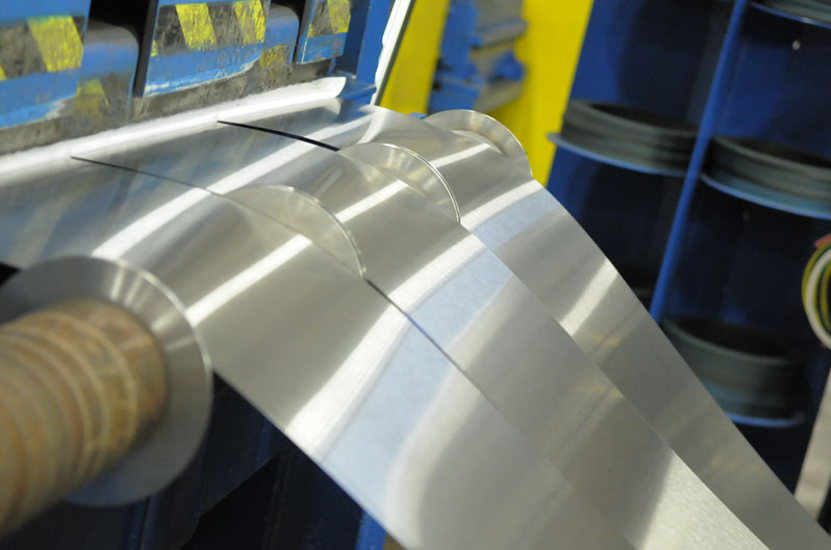

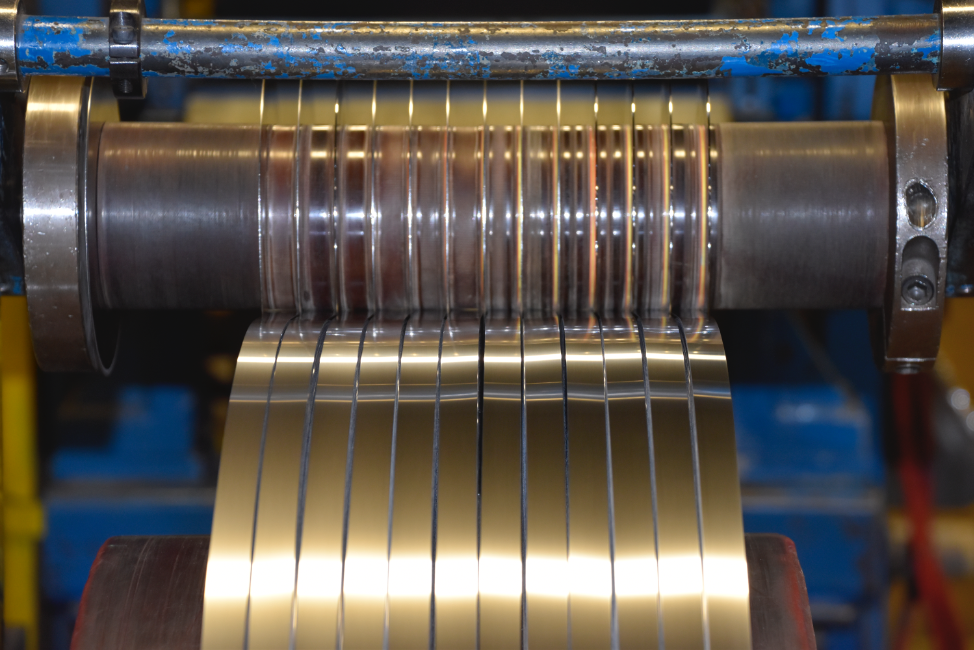

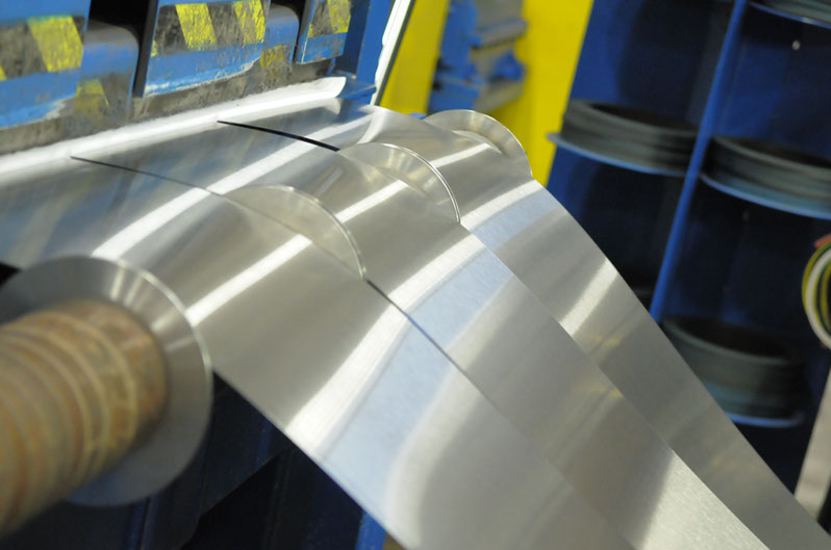

304 and 304L Stainless Steel Slitting: NKS Stainless Steel Slitting Company in Tulsa, Oklahoma

304 and 304L stainless steel are alloys from the 300 series of stainless steel that are great for manufacturing purposes. They are made up of chromium, nickel, and carbon, giving them unique characteristics that make them great for a wide range of end uses. Both products offer excellent forming and welding properties, resistance to […]